One-stop Service/Saving Cost & Time

Molding Type

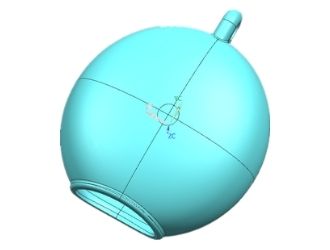

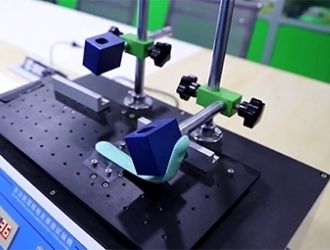

The compression molding process of silicone rubber is called thermal vulcanization. Compression molding is simpler than other silicone rubber molding type. The mold cost is low, and there is no complicated mold structure and system. Even silicon rubber products with complex structures can be produced. Utilize the soft and elastic properties of silicone rubber.It can be forcibly eject mold without damaging the product.